Rising Demand for Automation Solutions

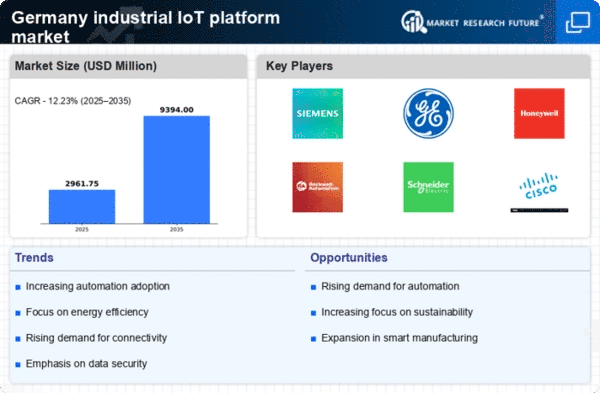

The industrial iot-platform market in Germany is experiencing a notable surge in demand for automation solutions. This trend is driven by the need for enhanced operational efficiency and reduced labor costs. Industries are increasingly adopting automated systems to streamline processes, which in turn boosts productivity. According to recent data, the automation sector is projected to grow at a CAGR of 8.5% through 2027. This growth is indicative of a broader shift towards smart manufacturing, where interconnected devices and systems play a crucial role. As companies seek to optimize their operations, the industrial iot-platform market is positioned to benefit significantly from this rising demand for automation.

Advancements in Connectivity Technologies

The industrial iot-platform market in Germany is benefiting from advancements in connectivity technologies. The rollout of 5G networks is expected to revolutionize industrial operations by providing faster and more reliable communication between devices. This enhanced connectivity facilitates real-time data exchange, which is crucial for the effective functioning of IoT systems. As industries increasingly rely on interconnected devices, the demand for robust connectivity solutions is likely to rise. Reports suggest that the 5G market in Germany could reach €5 billion by 2025, indicating a strong potential for growth in the industrial iot-platform market as companies adopt these advanced technologies.

Increased Investment in Research and Development

Investment in research and development (R&D) is a critical driver for the industrial iot-platform market in Germany. Companies are allocating substantial resources to innovate and develop new IoT solutions that cater to the evolving needs of industries. The German government, alongside private sector players, is investing heavily in R&D initiatives, with expenditures expected to exceed €100 billion annually by 2025. This focus on innovation is likely to yield advanced technologies that enhance the capabilities of industrial IoT platforms. As a result, the industrial iot-platform market is poised for growth, driven by continuous advancements and the introduction of cutting-edge solutions.

Growing Focus on Sustainability and Energy Efficiency

Sustainability has become a pivotal concern for industries in Germany, influencing the industrial iot-platform market. Companies are increasingly prioritizing energy efficiency and sustainable practices to meet regulatory requirements and consumer expectations. The German government has set ambitious targets to reduce greenhouse gas emissions by 55% by 2030, which necessitates the adoption of smart technologies. The integration of IoT solutions enables real-time monitoring and optimization of energy consumption, thereby supporting sustainability goals. This growing focus on environmental responsibility is likely to drive investments in the industrial iot-platform market, as businesses seek to leverage technology for greener operations.

Government Initiatives Supporting Digital Transformation

In Germany, government initiatives aimed at promoting digital transformation are significantly impacting the industrial iot-platform market. The German government has launched various programs to encourage the adoption of advanced technologies in manufacturing. For instance, the Industry 4.0 initiative aims to enhance the competitiveness of German industries through digitalization. This initiative is expected to allocate approximately €1 billion towards research and development in smart technologies. Such support not only fosters innovation but also creates a conducive environment for the growth of the industrial iot-platform market, as companies align with national strategies to modernize their operations.